Sell-through rate is a comparison of the inventory amount sold and the amount of inventory received from a manufacturer. Stock to sales ratio = $ inventory value / $ sales value Sell-through Rate This broad calculation can be used to adjust the stock to maintain high margins.

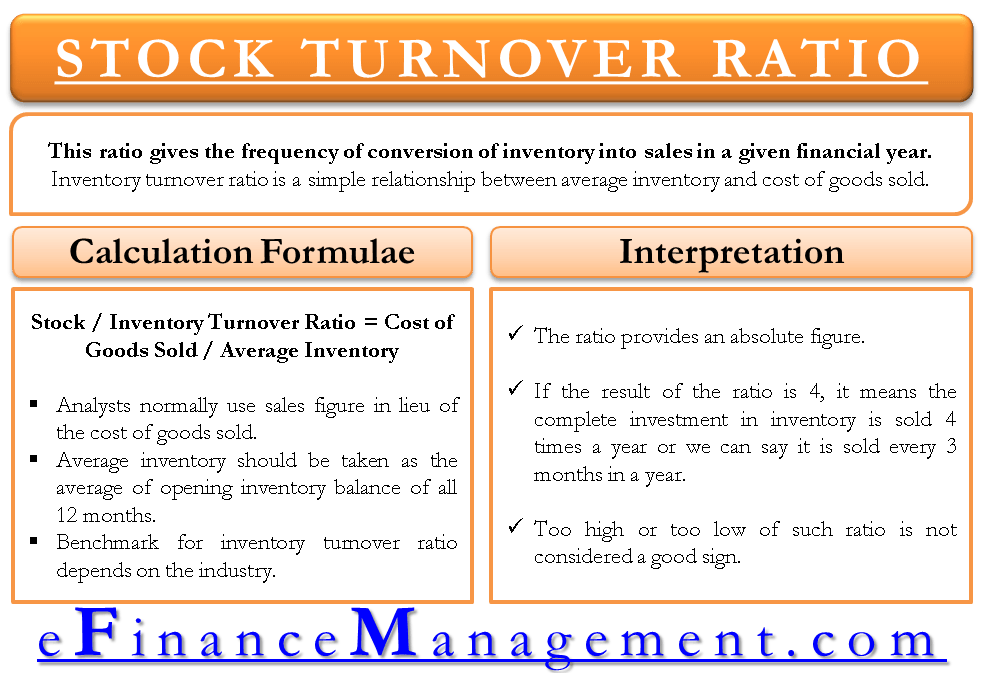

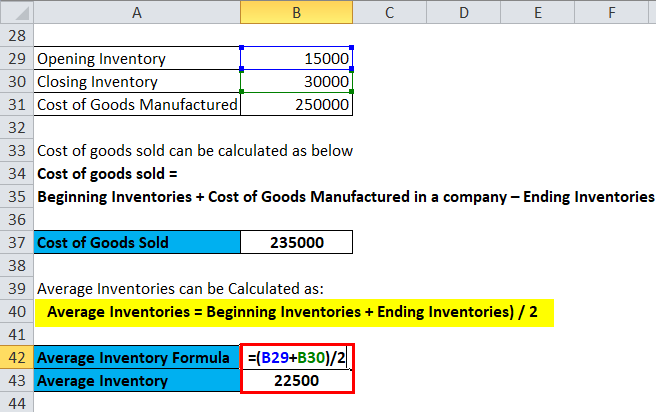

Stock to sales ratio is the measure of the inventory amount in storage versus the number of sales. Weeks on hand = (average inventory for period / cost of sales for period ) x 52 Stock to Sales Ratio Weeks on hand demonstrates the average amount of time inventory sells per week: a high weeks on hand measure shows inefficient movement, while a low weeks on hand rate shows efficient inventory movement. Use this formula to calculate days on hand:ĭays of inventory on hand = (average inventory for period / cost of sales for period ) x 365 Weeks on Hand This daily interval is the most common timeframe after an annual range. Inventory turnover rate = cost of goods sold / average inventory Days on Handĭays on hand (DOH), also known as the average days to sell inventory (DSI) or average age of inventory, is the rate of inventory turns by day. Use this formula to calculate inventory turnover rate:

Inventory rate measures how well a company makes sales from its inventory. You can use the inventory rate to determine if a business has too much inventory compared to how much of its stock is selling. Inventory Turnover RateĪlso known as inventory turnover ratio or inventory turn, inventory turnover rate is the number of times a company sells and replaces its stock in a period, usually one year. Set up these KPIs to mesh with organizational goals, and use them to optimize the sales teams’ performance. You can use sales metrics to better compete in the marketplace and help your sales team to win deals and collaborate. By discovering problem areas, leaders can implement process adjustments and track their improvement. Categorizing KPIs by operation type lets leaders focus on areas in need of change. How Do You Measure Inventory Management?īusinesses assess inventory management using different metrics for different business operations. KPIs in inventory management systems can show progress, where processes need work or where they find success. You can easily track KPIs using inventory management systems. In inventory management, KPIs matter because they offer information about turnover, sales, demand, costs, process success, relationships and more. Key performance indicators (KPIs) in inventory management are metrics that help you monitor and make decisions about your stock. Experts offer advice and tips for your success. Learn everything you need to know about inventory management KPIs and metrics, including when to use them, formulas and the difference between sales, receiving, operational and employee KPIs. East, Nordics and Other Regions (opens in new tab)

0 kommentar(er)

0 kommentar(er)